Solution

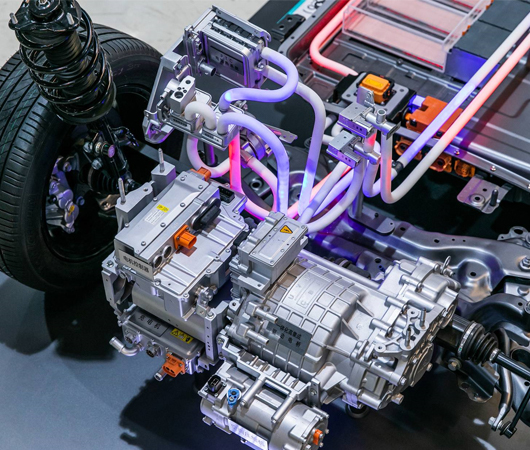

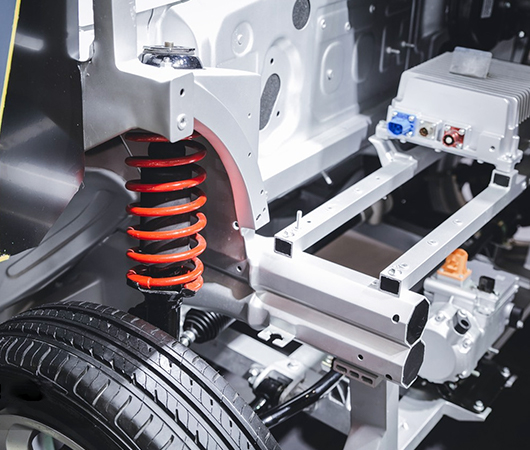

The design, research and development, and production of mechatronics integration meet your diverse needs

3 High capacity guarantee,IATF16949 System certification

Provide more advanced, high-performance, reliable and durable Automotive electronic parts in all aspects

About

Longtech

Longtech was established in August 2003 and listed on the GEM of Shenzhen stock Exchange in December 2020.We are an intelligent controller and intelligent products R&D,design, production and sales, for the automotive electronics field to provide all kinds of parts products and corresponding solutions company. Since obtaining certification related to the automotive industry system in 2013, Longtech has been exercising its quality control and process supply capabilities, and has established a cooperation mechanism with scientific research institutes to establish an automotive innovation platform. It now has systems, hardware, software

IATF16949

System certification

Multiple qualification certifications, in line with international standards

News

Sharing and Discovery

Corporate News